5 MEWP Safety Tips

Mobile Elevated Work Platforms (MEWPs) have revolutionized the way we approach tasks that require working at heights, offering a flexible and efficient solution for various industries. However, like any piece of heavy machinery, MEWPs come with their own set of safety risks if not operated and maintained properly. Ensuring the safety of operators and bystanders is paramount, and this can be achieved by following a series of best practices and guidelines. In this article, we will delve into 5 critical MEWP safety tips, highlighting the importance of training, inspection, proper use, stability, and emergency preparedness.

Key Points

- Operator training is essential for safe MEWP operation

- Regular machine inspection can prevent accidents

- Understanding and adhering to MEWP operational guidelines is crucial

- Ensuring MEWP stability is vital for preventing tipping accidents

- Having an emergency response plan in place is critical

Operator Training and Competence

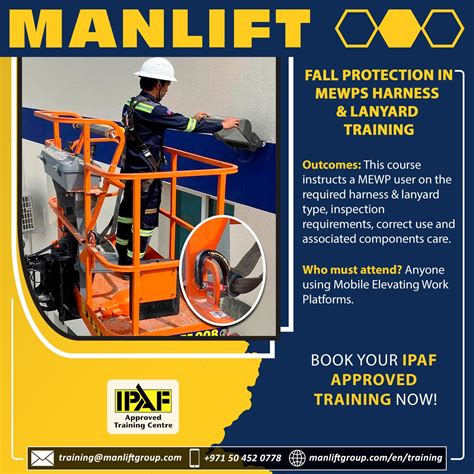

One of the most critical factors in MEWP safety is the training and competence of the operator. According to the International Powered Access Federation (IPAF), operators should undergo comprehensive training that covers both theoretical knowledge and practical skills. This training should include understanding the MEWP’s operational and safety features, learning how to perform pre-operational checks, and practicing safe operation techniques. Operators must also be aware of their responsibilities and the risks associated with MEWP operation. Employers have a legal obligation to ensure that their employees are properly trained before they are allowed to operate a MEWP. IPAF certification or equivalent is often considered the standard for demonstrating operator competence.

Pre-Operational Checks and Inspection

Before each use, a thorough pre-operational check of the MEWP is essential to identify any potential issues that could lead to accidents. This check should include inspecting the machine’s tires, brakes, hydraulic systems, and all safety devices such as alarms and sensors. Any defects or malfunctions should be reported and rectified before the MEWP is put into operation. Regular, more detailed inspections should also be scheduled as per the manufacturer’s recommendations to ensure the MEWP remains in good working condition. Record-keeping of these inspections is crucial for tracking the maintenance history of the MEWP and for compliance with regulatory requirements.

| Inspection Type | Frequency | Purpose |

|---|---|---|

| Daily Pre-Operational Check | Before each use | Identify immediate hazards |

| Regular Inspection | As per manufacturer's schedule | Maintain machine condition, comply with regulations |

Proper Use and Operational Guidelines

Adhering to operational guidelines is fundamental to safe MEWP operation. Operators should always follow the manufacturer’s instructions and safety guidelines. This includes understanding the MEWP’s load capacity and never exceeding it, being aware of the surroundings to avoid collisions or entanglements, and ensuring that all safety features such as guardrails and gates are in place and used correctly. Situational awareness is key, as conditions such as weather (e.g., strong winds, icy surfaces) can significantly impact the safe operation of the MEWP.

Stability and Leveling

Ensuring the MEWP is stable and level is crucial for preventing tipping accidents, which can be catastrophic. Operators should use outriggers or stabilizers as recommended by the manufacturer and ensure the ground is firm and level before elevating the platform. The MEWP should be positioned to allow safe access and egress, and operators must be cautious of slopes and uneven surfaces. Understanding the stability indicators and leveling systems of the MEWP is essential for maintaining stability.

Emergency Preparedness

Despite best efforts, emergencies can still occur. Having a well-planned emergency response in place can significantly reduce the risk of injury or damage. This includes training operators in emergency procedures such as rescue operations from heights, having a first aid kit on site, and ensuring that there is a means of communication available at all times. Regular drills can help prepare teams for potential emergencies, ensuring a swift and effective response.

What should I do in case of a MEWP emergency?

+In case of a MEWP emergency, stay calm and follow the emergency procedures outlined in your training. This may include alerting others in the area, securing the MEWP if possible, and calling for professional help. Never attempt a rescue without proper training and equipment.

How often should MEWPs be inspected?

+MEWPs should be inspected daily before use and undergo more detailed inspections at intervals recommended by the manufacturer, typically every 3 to 6 months, depending on usage and environmental conditions.

What is the importance of operator training for MEWP safety?

+Operator training is crucial for MEWP safety as it equips operators with the knowledge and skills to operate the machine safely, understand its limitations, and respond appropriately in emergency situations.

In conclusion, the safe operation of MEWPs requires a multifaceted approach that includes comprehensive operator training, regular machine inspection, adherence to operational guidelines, ensuring stability, and being prepared for emergencies. By following these 5 MEWP safety tips and maintaining a vigilant attitude towards safety, we can significantly reduce the risk of accidents and ensure a safer working environment for everyone involved.